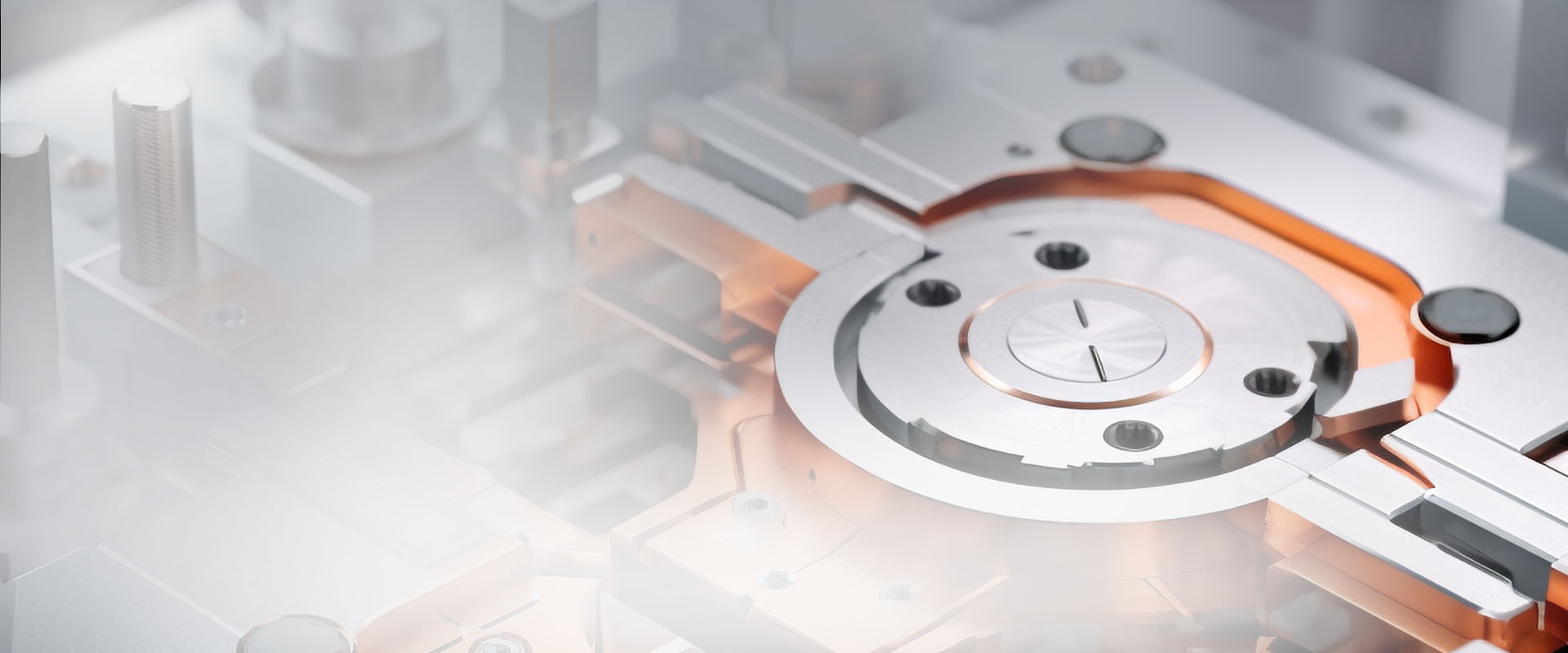

Precision Mold Design and Manufacturing

-

MIM Molds

MIM Molds -

Plastic Molds

Plastic Molds -

Restriking Molds

Restriking Molds -

Jigs and Fixtures

Jigs and Fixtures -

Inspection Tools

Inspection Tools

In the field of precision mold manufacturing, the company possesses industry-leading technologies such as high-speed milling (HSM), ultra-precision mirror EDM (Electrical Discharge Machining), and oil-based slow wire EDM. By incorporating linear motor drive systems and new-generation power control, we achieve machining precision of ±0.001mm, ensuring high responsiveness and stability. Combined with multiple precision positioning technologies used in mold assembly, the overall manufacturing precision of our molds can reach ±0.003mm. Specifically, our advantages include: