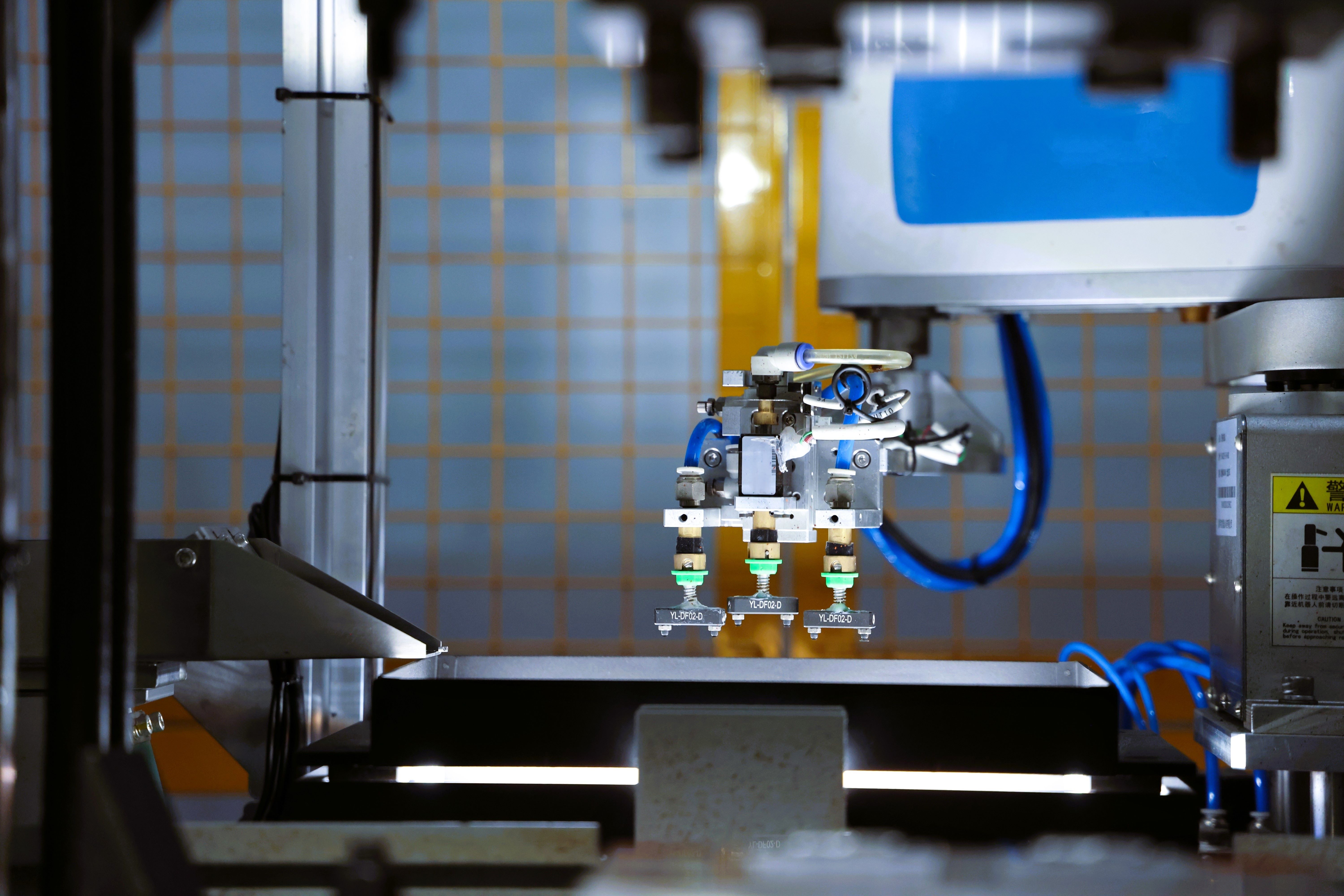

Currently, the company has automated its main manufacturing processes and is continuously advancing towards full-process automation and intelligent manufacturing through ongoing technological iterations. The high level of automation enables some production lines to operate continuously without human intervention, significantly reducing downtime and production interruptions, thereby improving overall efficiency and capacity utilization of the production lines. This also helps achieve high-precision and stable process control.

Automated equipment can precisely execute preset production processes, reducing human error and variability, thus enhancing product quality stability and consistency. With real-time monitoring and adjustments by automated equipment, the company can quickly respond to changes on the production line and make timely adjustments, ensuring that the production process remains in optimal condition.