-

Polishing

Polishing -

Magnetic Grinding

Magnetic Grinding -

Tumble Grinding

Tumble Grinding -

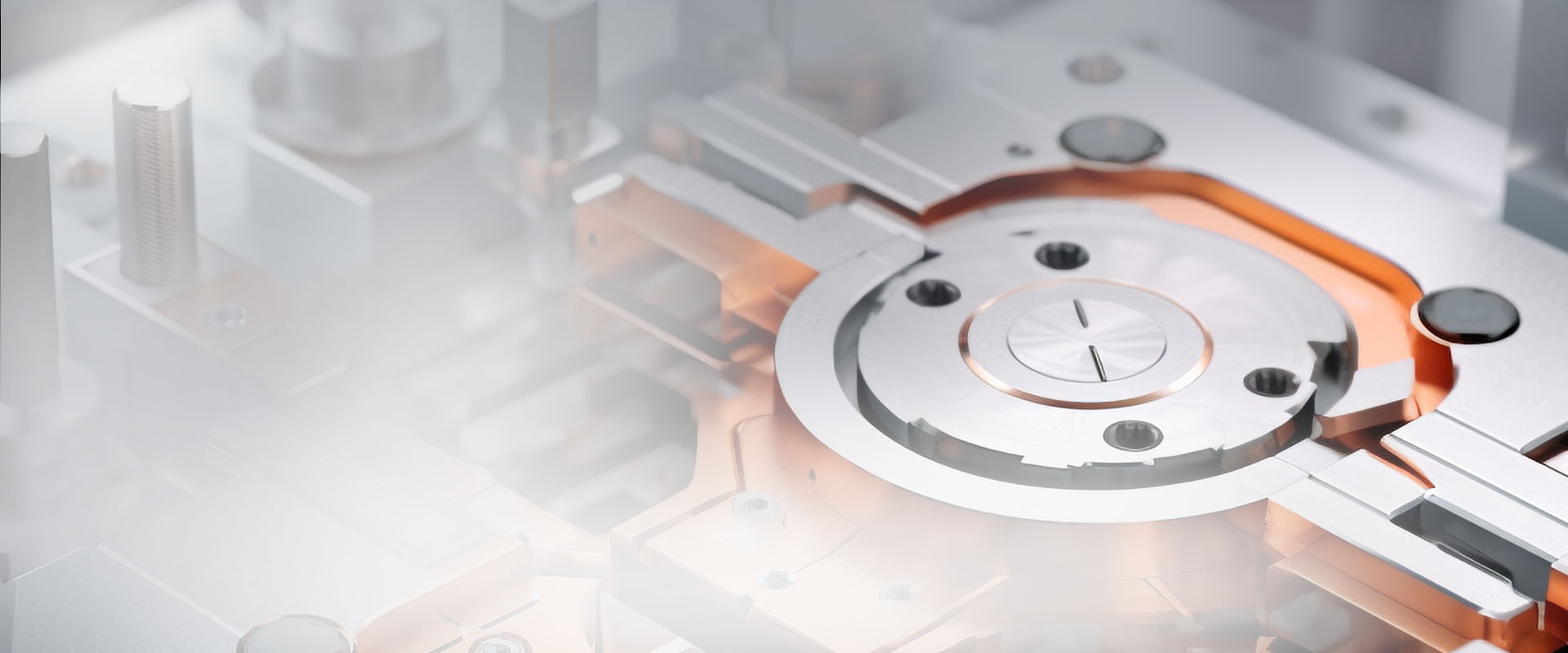

Flat Grinding

Flat Grinding -

Sandblasting

Sandblasting

Our surface treatment services utilize a variety of techniques to comprehensively improve and protect the surface performance of metal parts. These methods include polishing, magnetic grinding, tumble grinding, flat grinding, and sandblasting. We are able to meet a wide range of needs, from enhancing the aesthetic appeal of parts to improving their corrosion resistance, wear resistance, and specialized surface properties.

These diverse surface treatment technologies cover various metal materials and part designs and can be customized according to specific customer requirements. Whether aiming for a high-quality appearance or requiring specific surface functionalities, our technology and expertise ensure that customers' parts achieve optimal aesthetics, performance, and durability.

Through our professional surface treatment techniques, customers can enjoy comprehensive support for customized solutions, ensuring their products maintain competitiveness and longevity in the market.