Metal Injection Molding (MIM) is a form of additive manufacturing that offers high design freedom and near-net shape capabilities, making it suitable for the mass production of metal products with complex three-dimensional shapes and high dimensional accuracy. Compared to other metal processing technologies, MIM has significant advantages. The MIM technology is a comprehensive process that includes several stages such as raw material feedstock development and formulation, mold design and manufacturing, injection molding, debinding, sintering, and customized post-processing. Each stage involves specialized know-how. Currently, the company has developed core competencies in every aspect of MIM technology, maintaining a leading position in the industry.

-

MIM

MIM -

3D Printing

3D Printing -

CNC

CNC -

Stamping

Stamping -

Wire Cutting

Wire Cutting -

Laser Processing

Laser Processing

MIM(Metal Injection Molding)

MIM(Metal Injection Molding)

3D Printing

3D Printing

PUT closely follows the development of cutting-edge industry technologies and actively expands its business layout. Currently, the company has technical reserves in both direct and indirect 3D printing.

CNC

CNC

Our CNC machining services are specifically designed for the high-precision mass production of complex parts. Utilizing high-performance CNC machines and our professional expertise, we ensure the highest level of precision and consistency in part machining, meeting the most stringent quality standards.

Stamping

Stamping

Wire Cutting

Wire Cutting

Our wire cutting technology employs innovative applications in the production of precision components, surpassing its traditional use in mold manufacturing. Through this technology, we achieve high precision and high-quality output in machining precision parts from hard materials. As the largest capacity provider in South China, we offer strong support for the processing of precision parts, meeting a wide range of customer needs in project and product development.

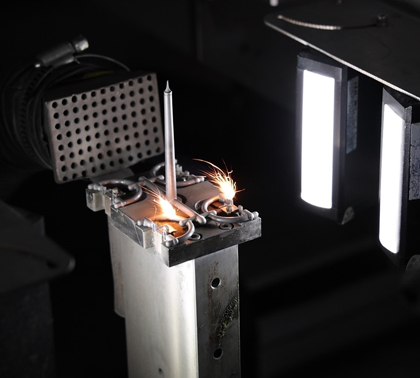

Laser Processing

Laser Processing

The company possesses comprehensive laser processing capabilities, including laser cutting, laser welding, and laser marking. Supporting various material types, these technologies are suitable for high-precision mass production and large-scale manufacturing needs. The application of laser technology enhances processing flexibility and production efficiency, ensuring the efficient execution of projects.